In-space nondestructive evaluation

Early conceptual design of first-stage in-space demonstration experiment

Early conceptual design of first-stage in-space demonstration experiment

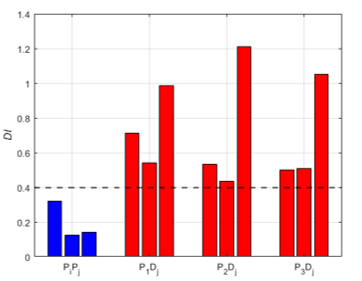

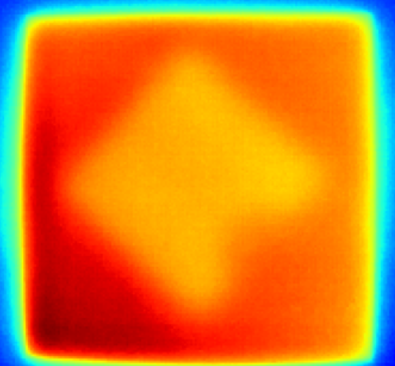

Manufacturing satellites in space could provide a rapid response and great flexibility to mission needs. The structural components of these satellite could be printed in space. Through hybrid additive manufacturing, printed circuits and other pre-made modules, such as solar cells, would be integrated with host structures. However, such structures are susceptible to stress-induced failure due to mismatch in thermal expansion properties and other long-term degradation such as radiation damage. As such, it is of utmost importance for mission success to diagnose structural integrity. This inspection could happen through a) in-process monitoring, b) post-assembly verification, and c) lifecycle monitoring. However, no broadly applicable in-space nondestructive evaluation (NDE) solutions exist that are efficient and reliable. Thus, we propose to investigate automated, real-time, data-based methods aligned with the ISAM National Strategy.