California State University, Northridge at 18111 Nordhoff Street, Northridge, CA 91330 / Phone: 818-677-6229 / © 2018 CSU Northridge

MSE 409

Khashayar “Kash” Behdinan

This course is designed to contribute primarily to:

Knowledge of and ability to prepare processes, design fixtures and tooling, and prepare raw material

Ability to design and write NC programming

Knowledge to design machining processes using manufacturing equipment

Ability to understand and to develop alternative machining processes for different features

Ability

to

conduct

a

project

to

design

object,

and

computer

machining

and

tooling

conditions,

and

produce the part

Course Objectives

Course Plan

Topics in computer-aided manufacturing (CAM) . Fixed, programmable, and flexible automation; introduction

to numerical control technology; manual NC programming; post processing; graphical NC programming; NC

programming with CAD/CAM systems. Selection and design of tooling

.

COURSE DESCRIPTION

1.

S.C. Jonathan Lin, Computer Numerical Control from Programming to Networking,

Delmar, Delmar Publishers

2.

" Computer-Aided Manufacturing", Chang, Wysk and Wang, Pearson, 3rd edition

3.

Mill/Design Applications Guide, Mastercam

4.

Various manuals and handouts

TextBook

ILecture:

Introduction to CAD/CAM

CAD: Graphics, and Transformations.

Geometric Modeling.

Introduction to Geometric Modeling.

Geometric Modeling Approaches.

Wireframe Modeling.

Surface Modeling.

Solid Modeling.

Data Exchange.

Concurrent Engineering.

Computer Aided Process Planning.

Computer Control of Manufacturing Systems.

Lab:

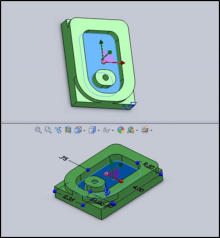

Introduction to CAM (1 week)

Manual Cutting (1 week)

NC programs generation (1 week)

Automatic Cutting with Compensation (2 weeks)

Surface Cutting (1 week)

Tool and Cutting (1 week)

Design Practice (1 week)

Fixture and Cutting (1 week)

Drill Toolpaths (1 week)

3D Contour Toolpaths (2 weeks)

Advanced Pocket Toolpaths, Final Project (2 weeks)

Final Project (1 week)

Fundamentals of Computer-Aided Manufacturing

MSE 409 -L