California State University, Northridge at 18111 Nordhoff Street, Northridge, CA 91330 / Phone: 818-677-6229 / © 2018 CSU Northridge

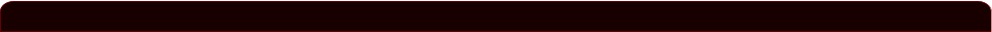

Virtual Commissioning

This process, known as virtual Commissioning uses 3D technology to create a simulation model of a factory floor process so that changes and upgrades can be tested before they are implemented into actual plant systems using a real controller. By simulating and validating your automation equipment virtually, we can confirm that all equipments will work as expected-significantly reducing system installation cost and startup time. This approach can also lead to better software quality and increased safety. If you are interested to join this research please send an email to : khashayar.behdinan@csun.edu

Research Summary

Automation

Robotics

Industrial Networks & Communications

Pneumatics & Hydraulics

Artificial Intelligence

Simulation and Modeling

Automation and

Robotic Laboratory

(JD1115)

Khashayar “Kash” Behdinan

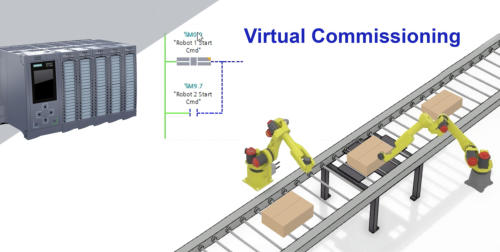

Factory Flow Simulation

Engineers can design factory layouts, as they define, simulate, and analyze multiple

production scenarios, in a realistic 3D environment. If process planning data is not

available, they can start from scratch, positioning resources and designing material

flows. They can define production equipment, line behavior and material flow logic. If

resource programming has been done, robot and NC machine programs as well as

human tasks are natively integrated into the model and can be simulated

This research includes:

If you are interested to join this research please send an email to :

khashayar.behdinan@csun.edu

Modeling and simulation at multiple levels of detail

Working with multiple attributes, engineers can tweak a large range of

values and run 3D simulations to arrive at an effective flow.

They can assign a worker to a transfer point, for example, and adjust

worker speed and transfer time to accord with the weight of the product.

They can adjust conveyor speed to the timing requirements of a robot or

an NC machine.

Speedy process evaluation

Rapid equipment feasibility and performance studies.

Measurements and

Mechatronics

Laboratory

(JD1616)

Modeling & optimizing electric drive systems

Modeling research to covers electric machines with associated

controllers, e.g. field-oriented control and inverters with corresponding

modulation methods, e.g. space-vector modulation

The research includes :

• Speed/torque controller design of electrified powertrains

• Analysis of different powertrain configurations

• Controller development and design

• Loss estimation of inverters and electric machines for thermal

simulations

• Voltage and current ripple effect studies

• Integrated vehicle models enabling energy consumption simulations

for electric vehicles

•Generating parameters for table-based models from physical models

If you are interested to join this research please send an email to :

khashayar.behdinan@csun.edu

Data Analysis and Decision Making

Instrumentation

Signal Conditioners

Data Acquisition

Autoamtic Control

Artificial Intelligence

Research Areas

William F. MacDonald

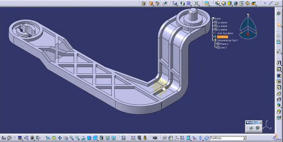

Computer Aided Design

Graphics Laboratory

(JD 1126)

Research Areas

Computer Aided Design

Computer Aided Manufacturing

Advanced Manufacturing Process

Additive Manufacturing

Operation Systems and

Management

Department

Data Analysis and Decision Making

Project Management

Supply Chain Management

Operation Management

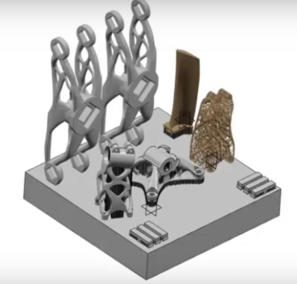

Generative Design Optimized for 3D Printing

If you are interested to join this research please send an email to :

khashayar.behdinan@csun.edu

Integrated applications for additive manufacturing

Materials research for additive process

Multiphysics simulation-based optimization and predictive

analytics

Print to Perform to focuses on the core theme of Virtual Printing

The research includes :

Micro-structure predictions, as-built material properties, and residual

stresses calculations

Research Areas

Research Areas

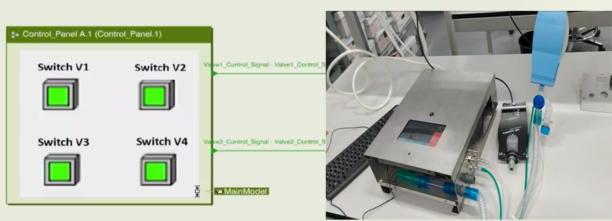

The Digital Twin of Ventilators Project will implement the following:

Objective1:

Study the means by which real Ventilators are developed as well as their related control programs and test them before being constructed . This is done by complete literature review of similar practices and examine lessons learned.Objective2:

Analyze debugging and correction efforts to significantly reduced implementing and running the real Ventilators.Objective 3:

develop a Pilot Project to study, analyze and determine the behavior of human lung and modeling of Ventilator by using a digital twin platform. If you are interested to join this research please send an email to : khashayar.behdinan@csun.edu

Digital Twin of Ventilator Using Simulation Environment

The Digital Twin of Ventilators Project will implement the following:

Objective1:

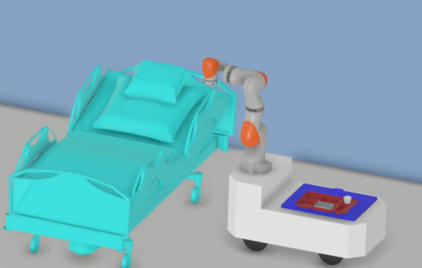

In this Research you will help design, manufacture, and program an autonomous prototype robot that will be used to help pateints and First responders . If you are interested to join this research please send an email to : khashayar.behdinan@csun.edu

Autonmous Robot to help First responders